Product Features:

Product Features:

This machine delivers label, gummed with resinous glue, from turret to vacuum belt and from belt to the bottle surface. It is possible to quickly exchange different bottle and label sizes with ease. It is simple in operation, neat, easy to clean up and suitable for round container labeling applications in industries, such as chemical, pharmaceutical, food, winery, etc.

[wptab name=’Automatic Top Labeler’]

Product Features:

Product Features:

The machine all made up of stainless steel and aluminium alloy from main board, main frame, conveyor belt table, legging, to interface. Main frame is qualified according to G.M.P. standard. Automatically detect the length and label positioning of containers to prevent mislabelling. System notifies the end, shortage, broken of label and has the function of counting and is suitable for independent operation, also possible for connection with line operation. The conveying belt can be taken out if it is necessary. Horizontal or vertical labelling is applied according to practical needs.

[/wptab]

[wptab name=’Top & Bottom Labeler’]

Product Features:

Product Features:

The machine all made up of stainless steel and aluminum alloy from main board, main frame, conveyor belt table, legging, to interface. Main frame is qualified according to G.M.P. standard.Automatically detect the length and label positioning of containers to prevent mislabeling.System notifies the end。Bshortage。Bbroken of label and has the function of counting.Suitable for independent operation, also possible for connection with line operation.The convey ing belt can be taken out if it is necessary. Horizontal or vertical labelling is applied according to practical needs.

[/wptab]

[wptab name=’Automatic Wrap-Around Labeler’]

Product Features:

Product Features:

The machine all made up of stainless steel and aluminum alloy from main board, main frame, conveyor belt table, legging, to interface. Main frame is qualified according to G.M.P. standard.When labelling, the bottle will automatically rotate to allow the labeling device to apply the pressure for labeling.Label position, height, and angle can be adjustable by hand wheel.Bottle correction, split and label ironing functions.No experience users only need to touch of a button and, any type of label can be setup simply.

[/wptab]

[wptab name=’Automatic Wrap-Rolling Labeller’]

Product Features:

Product Features:

The machine all made up of stainless steel and aluminum alloy from main board, main frame, conveyor belt table, legging, to interface. Main frame is qualified according to G.M.P. standard.When labelling, the bottle will automatically rotate to allow the labeling device to apply the pressure for labeling.Label position, height, and angle can be adjustable by hand wheel.Bottle correction, split and label ironing functions.No experience users only need to touch of a button and, any type of label can be setup simply.

[/wptab]

[wptab name=’Automatic Front And Back Labeler’]

Product Features:

Product Features:

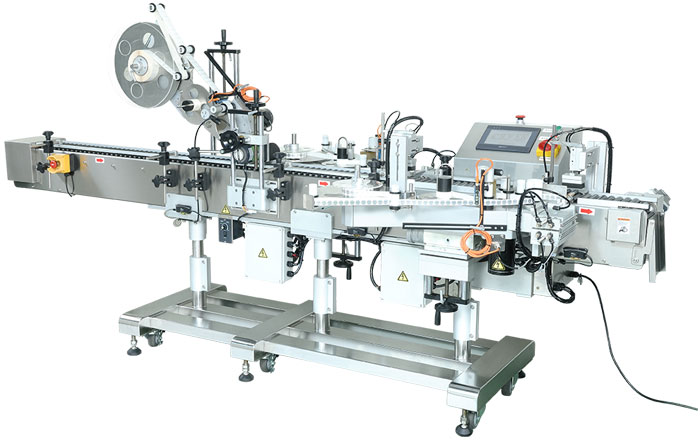

The machine all made up of stainless steel and aluminum alloy from main board, main frame, convey belt table, legging, to interface. Main frame is qualified according to G.M.P. standard.The control system provides in one side or in front and back labelling choices.No experience users only need to touch of a button and, any type of label can be setup simply.Suitable for independent operation, also possible for connection with line operation.The Auto Labelling has been designed for labor saving, and cost reduction in bottle labelling operations.Bottle correction, split, press, and label ironing functions.

[/wptab]

[wptab name=’Automatic Suck Labeling’]

Product Features:

Product Features:

The machine all made up of stainless steel and aluminum alloy from main board, main frame, convey belt table, legging, to interface. Main frame is qualified according to G.M.P. standard.Touch Control LCD screen in version of English.System notifies the end。Bshortage。Bbroken of label and has the function of counting.With its innovative design, its operation is so simple that even a primitive man can use.Any mistake will show on LCD display.Automatically detect the length and label position ing of containers to prevent mislabeling.

[/wptab]

[end_wptabset]