Vacuum Pumps:

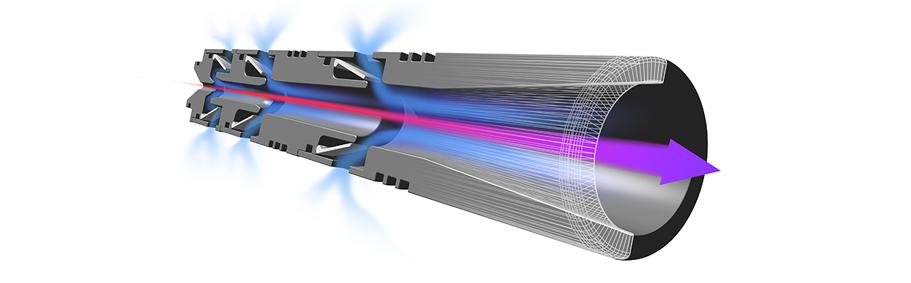

Piab vacuum pumps/vacuum generators are predominately based on the patented COAX® technology.

COAX® is an advanced solution for creating vacuum with compressed air. Based on Piab’s multistage technology, COAX® cartridges are smaller, more efficient and more reliable than conventional vacuum ejectors, which allow for the design of a flexible, modular and efficient vacuum system. A vacuum system based on COAX® technology can provide you with three times more vacuum flow than conventional systems, allowing you to increase speed with high reliability while reducing energy consumption.

[wptab name=’Inline’]

[wptab name=’Inline’]

Inline

PiINLINE are small light-weight inline ejectors that use the patented COAX® technology inside. They can be mounted directly on a hose close to the suction cup (or point of suction). Piab’s piINLINE ejector program offers much better performance with at least 40-50% lower energy consumption compared to competing inline single-stage ejectors in corresponding sizes.

[/wptab]

[wptab name=’Compact/Stackable’]

Compact/Stackable

Compact/Stackable

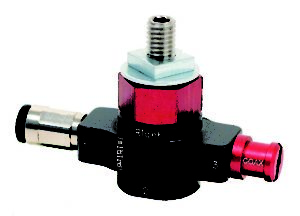

Compact/stackable vacuum pumps are air-driven multistage ejector families, based on COAX® technology, that come with integrated controls and special functions, such as on/off valve, blow-off valve, vacuum switch, energy saving function etc.. They are configurable platforms, making it easy to specify the exact control functions needed for the system.

[/wptab]

[wptab name=’Combined pump and gripper (VGS™)’]

Combined pump and gripper (VGS™)

Combined pump and gripper (VGS™)

A product design where different suction cups are integrated with vacuum cartridges based on the patented COAX® technology. The “vacuum gripper” makes selection, sizing and installation of a vacuum system easier. With a VGS™ you will enjoy the benefits of a more cost-efficient and reliable decentralized vacuum system.

[/wptab]

[wptab name=’Standard Design Pumps’]

Standard Design Pumps

Standard Design Pumps

These are vacuum pumps of a standard (classic) design and range from very small chip pumps to large capacity pumps. Most of the pumps have the COAX® cartridge inside, a vacuum system based on COAX® technology can provide you with three times more vacuum flow than conventional systems, allowing you to increase speed with high reliability while reducing energy consumption.

[/wptab]

[wptab name=’Suction Cups’]

Suction Cups

Piab offers one of the markets widest ranges of suction cups so that each application will have its own solution. You are welcome to tell us about your needs. We are your partner whatever your needs might be. Using suction cups is a lifting technique of many possibilities. You can, for example, handle board materials or concrete slabs, open bags, pick electronic components, label and hold objects. But different applications need different requirements.

[/wptab]

[wptab name=’Diaphragm Pumps’]

Diaphragm Pumps

The air-operated diaphragm pumps can be used for almost any low to high viscosity media, whether neutral or aggressive, whether flammable or abrasive, with or without solids, whether used with or without gas components. A wide range of different pump materials ensures optimum chemical resistance with the media to be pumped, and the optimum thermal resistance with a view to the liquid or ambient temperature. Because of their design principle, the air operated diaphragm pumps are qualified for a variety of difficult applications, especially in damp or hazardous locations

[/wptab]

[wptab name=’Drum pump set’]

Drum pump set

Drum pump set

The Jessberger drum pump sets are the perfect assistants for a quick and safe filling and transferring or emptying of drums and containers. Drum pump motor, pump tube, 2 m medium resistant hose and nozzle were composed cause of the firm’s experience over many decades and guarantee therefore, an immediate applicability and long life of these drum pumps.

The user can combine outside the ex-areas of each pump tube with each motor and helpful accessory and select their own drum pump set

[/wptab]

[wptab name=’Peristaltic Pumps’]

Peristaltic Pumps

Product Features:

Batch Transferring Pump is suitable for the tube wall thickness of 4.8mm, 6.3mm. Maximum flow rate is 35L/min, the largest pressure is 0.3Mpa. It has reasonable tight composition, easy to load the tube. The roller adopts planetary gear transmission, safe and reliable, at the same time it can prolong the tubing life.

[/wptab]

[wptab name=’Variable Peristaltic Pump’]

Variable Peristaltic Pump

Variable Peristaltic Pump

Product Features:

Variable Peristaltic pump flow rate from 0.005 ml per minute to 30 liters per minute. The pump is feasible for the clients which has minimum flow requirement that ranges between the aforementioned criteria. This liquid transfer equipment usually suitable for chemical dosing, spray for granulation, corrosive liquid transfer etc.

[/wptab]

[end_wptabset]