Injection Equipment

Yenchen has been specializing in manufacturing Pharmaceutical Machine in Taiwan for many years. We mainly provide Injection Equipment, Automatic Bottle Washing Machine, Oral Dosage Equipment and Ointment Equipment which can be widely applied to Pharmaceutical, Food and Chemical Industry. In addition, our main products also include Automatic Inspection Machine, Hot Air Sterilizer, Steam Sterilizer, Vial Washer, Distilled Water System and Dry Granulator. As a leading manufacturer of Pharmaceutical Machine, we offer above mentioned products with superior quality.

[wptab name=’Distilled Water System’]

Distilled Water System

Features

1. Divide into the single effect and multi- effect types

2. Sanitary welding grade: polishing inner and outer for above #320 polish

3. Water/vapor separable design to prevent non-qualified vapor to contaminate the distilled water

4. Can use for distilled water and pure water

5. Double protection control: Temperature and Diaphragm pressure controllers

6. An electric conductivity sensor at the water outlet for water degree controller : the qualified value can be adjusted according to different requirement.

7. All designs are according to the world safety pressure vessel standard ; and inspected by the government before delivery

8. With IQ/OQ validation reports

9. Design according with customer’s request from 50L/Hr~5000L/hr or more

10. SIP function available for condenser and piping fittings

11. All contacts with water quality are SUS316 and polish #320

12. Metering water supply and recording all important temperature

[/wptab]

[wptab name=’Vial Washer’]

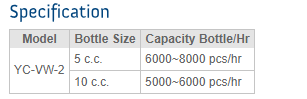

Vial Washer

Vial Washer

WASHING PROCESS (process selection can be varied)

Option 1: City Water → Pure Water → Air

Option 2: Pure Water → Distill Water → Air

Option 3: City Water → Detergent → Steam → Pure Water → Air

Option 4: City Water → Steam → Pure Water → Air

Features

1. Compact size.

2. Fast washing speed.

3. After place of vial, washing process is automatic.

4. Action of capping is control by foot step.

5. Using sanitary piping and filter which meets GMP standard.

6.Multi-safety device to ensure safeness.

7.PLC auto control system

[/wptab]

[/wptab]

[wptab name=’Ampoule Washer’]

[/wptab]

[wptab name=’Hot Air Sterilizer’]

Hot Air Sterilizer

Hot Air Sterilizer

Hot air sterilization is applicable to sterilization instruments which can tolerate high temperature and need to remain in sterilized condition. This process is commonly used for vial, ampoule, rubber stoppers and stainless steel instruments. Under the same condition, hot air sterilization needs a higher temperature to kill germs and micro-organisms than saturated vapor sterilization.

Structure

Sterilizer from the washing room and sterile room. Bottles are to be loaded into the washing room and to be sterilized by the sterilizer and loaded out from the sterile room. Fresh air in the sterilizer passes through a pre-filter, heated by the electric heater to become hot air. The hot air high temperature durable Hepa Filter which will result the particle counter of under class 100 before entering in the sterilizing camber. The air flow adjustable damper is installed at both sides at the sterilizing chamber to even the chamber temperature which helps exterminating germs and other micro-organisms to ensure that there Is no more than 0 germs alive in one million sterilized objects.

Features

1. Safety sterilized welding: Sterilizing room is welded using stainless steel 5U5304 which avoids contaimination from the iusulation material after long use.

2. Complete closure: During the process of sterilization and when the sterilizer is oft, the dampers are always tightly closed to ensure the sterilizing chamber is fully closed.

3. High efficiency filters: The absolute Hepa 99,97% filter can bare above 350t and can particles below 0.3 Micro.

4. High temperature durable seal; The seal of the circulation blowers made of carbon filter to bare the high temperature of hot air passing Through, to prevent air leakage and to avoid contamination.

5. SCR control: SCR (Silicon Control Resister is adopted to ensure the most smooth curve of temperature when heating.

6. Evenly distributed hot cir: The air flow adjustable baffles installed at both ‘sides of the sterilizing chamber can ensure that hot air spreads evenly.

7. Postive, negative pressure design: To avoid contamination, the sterilizing chamber has negative pressure before the completion of sterilization and positive pressure when sterilizing process completes.

8. Inter-locked with safety switches: floors are inter-locked with safety switches (only the door on the sterile room side can be opened open when the sterilizing process completes.)

9. Fully automatic control: Programmable control tar drying, heating, sterilizing and coaling cycle.

10. Pre-set timer available: Pre-set time Is available for any preferred time. (can preset the sterilizing process before off duty, the next ‘day the goods will be ready.)

11. Testing holes available: DOP hole, particle counter test hole and validation testing holes are available for inspection

12. Temperature recorder: Can completely record the whole sterilization process of temperature progress through out sterilization.

13. Over heat protection: Double temperature control is equipped to ensure safety.

14. Monometer: Can check the resistance of the filter.

15. Complete original records of sensors and calibration of all instruments are available.

[/wptab]

[wptab name=’E.O.Gas Sterilizer’]

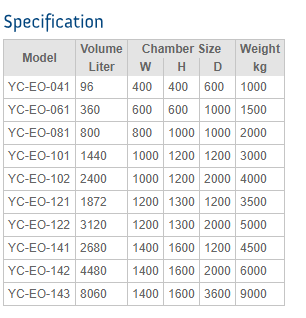

E.O.Gas Sterilizer

E.O.Gas Sterilizer

Our company is professional supplier of Sterilizer, Compress Machine, Compressing Machine, and Hot Air Disinfection.

Structure

E.O. Gas Sterilizer is consist of sterilizing chamber, jacket, vacuum system, hot water circulation system, E.O. gas supply system, heating system, de-vacuum system and control system.

Features

1. Leakage Test: Before every operation, perform leakage test will secure the safety.

2. Accuracy Control: To Ensure the heat distribution and humidity is well controlled during the sterilization.

3. Automatic Control: The program is fully automatic controlled by PLC.

4. EO Gas Dissolving Tank: Vacuum pump sucks out the gas into the dissolving tank and dissolves the gas in the water, then expels.

[/wptab]

[/wptab]

[wptab name=’Steam Sterilizer’]

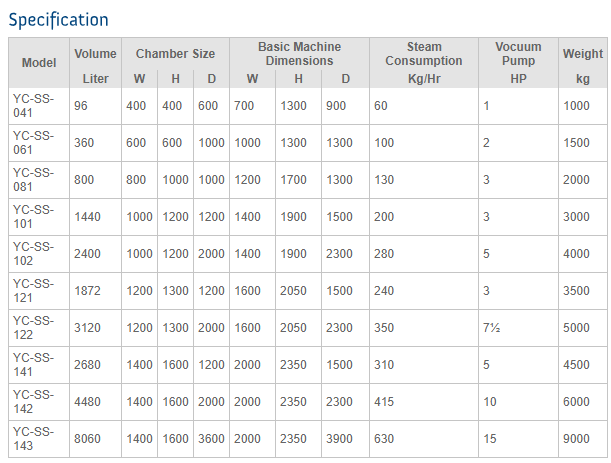

Steam Sterilizer

Steam Sterilizer

The sterilizer is commonly located between the washing room and sterilization room. The extermination of germs and micro-organisms can be achieved when the object for sterilizing is in the contained sterilization room with an essential high temperature and sufficient time; and therefore safer and more reliable products or instruments can be obtained.

Features

1. Oil hydraulic door: the door clamping device uses an oil hydraulic cylinder to drive clamp for easier and contained operation.

2. Steam piping: steam piping fitting is made of sanitary pipe. The steam passes through one micro pre-filter 1μm

3. Even steam distribution: by vacuum pump and entrance of steam into sterilization room during sterilization to achieve ±1℃ sterilization temperature.

4. Fully automatic control: Adopt PLC control system, when the conditions have been set, the process will be controlled automatically.

5. Temperature recorder: records the temperature progress distribution completely and record pressure changes throughout whole sterilization process.

6. Inspection hole: validation testing holes are available for inspection.

7. Computerized Operation: the computer can calculate the FO figure and shows that there is no more than one germ alive in one million of sterilized objects.

8. Three functions in one: integrated sterilization, cooling and leakage test to save time, energy, space and labor.

9. Provide complete original record of sensors and calibration of all instruments.

[/wptab]

[end_wptabset]