[wptab name=’Cone Mill’]

Cone Mill:

The fast rotating impeller crushes the infeeding material onto the surface of the punch hole screen. The material will be crushed into the desired size through the screen.

Features:

1.Follow the regulations of cGMP, PIC/S GMP, FDA

2.WIP System is available

3.Explosion Proof System is available: Suitable for organic solvent

4.Multi-safety Interlock System:

a. Stop operation when the cover is not closed properly

b. Stop operation when the air pressure is not sufficient for the seal

5.Separated compressed air routes design to meet the good air quality: the compressed air for air seal will pass through an air filter. For the cylinder, the compressed air will pass through lubricating oil to ensure the air quality and lubrication

6.Unique design of the air seal: This design can prevent powder access into the main seal and the chopper to prevent powder dropping

7.The clearance between impeller and the bottom of mixing bowl is only about 0.5~0.8 mm; therefore, high mixing efficiency can be achieved

Applications:

Raw Material Grinding & De-agglomeration: It has the function of griding the lumps to smaller particle size. This can pre-process raw material to eliminate irregularities, therefore it will improve the mixing efficiency.

Size Reduction: Fix the oversize raw material t a smaller and uniform particle size.

Dry Granulation & Milling: Dry granulation can reduce granule/powder into desired range of particle size.

Wet Granulation & Milling: Wet material is reduced to a small and uniform particle size before drying. It produces small and uniform size fine powder form agglomerates that are produced by mixer. This is perfect for the dryer to take short time of achieving the uniform drying.

[/wptab]

[wptab name=’Fitz Mill’]

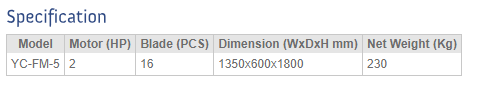

Fitz Mill:

Using high speed rotating blades to crush or grind raw materials to a desired size which is smaller than the perforated plate screen.

Speed is adjustable to suit different material.

Perforated plate screen: mesh size can be selected to meet the processing requiements.

Functions:

CRUSHING: Crush raw material into small granule or powder.

MILLING: Process larger and irregular granules into smaller and even size.

Features:

1. High production output

2. Meet with GMP standards

3. Special bearing cooling system (by water or air) for high-speed operation that prevents the high heat damaging the product and ensures product quality.

4. Stainless steel blades provide a durable cutting edge. 180 degree screen design enables better and faster milling results.

5. Suitable for dry and wet granules

6. Ease of screen changeover (perforated plate screen)

7. Easy to operate, clean, and assemble

8. Discharge system in cope with vacuum suction device to eliminate dust contamination. (Optional)

[/wptab]

[/wptab]

[wptab name=’Power Mill’]

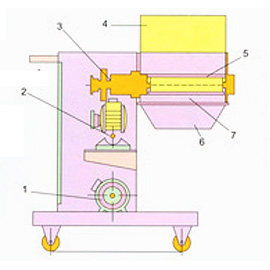

Power Mill:

Using high speed rotating blades to crush or grind raw materials to a desired size which is smaller than the perforated plate screen.

Speed is adjustable to suit different material.

Function:

CRUSHING: crush raw material into small granule or power.

MILLING: process larger and irregular and irregular granules into smaller and even sized granules.

Features:

1. High production output.

2. Meet with GMP standards.

3. Special bearing cooling system(by water or air) for high speed operation thatprevents the hight heat damaging the product and ensures product quality.

4. Stainless steel blades provide a durable cutting edge.

5. 180 degree screen design enables better and faster milling results.

6. Suitable for dry and wet granules.

7. Ease of screen changeover(perforated plate screen)

8. Easy to operate , clean , and assemble.

9. Discharge system in cope with cacuum suction device to eliminate dust contamination.(OPTIONAL)

[/wptab]

[wptab name=’Oscillating Granulator’]

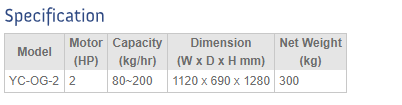

Oscillating Granulator:

Dry Granulator is designed to process bigger and irregular granules into uniform sizes of granules after the drying proces.

Mechanical Theory:

1.The principle of the Dry Granulator is to apply two continuously turning central-rollers which press out even sizes of dry granules through a wide screen (or a punch hole plate screen).

2.This machine not only has a sieving function, but also a milling function, which makes better quality, faster production, and greater quantity possible.

3.Granulation screen:mesh size can be varied to suit different type of products.

Features:

1. High production output.

2. Meet with GMP standards.

3. The special design of the patent-shaped roller enables better and faster granulating results.

4. special seal and bearing designs prevent black spots and ensure product quality.

5. Forward and reverse rolling directions prevent blockage.

6. Ease of screen changeover(perforated plate screen)

7. Easy to operate, clean , and assemble

8. Discharge system in cop with vacuum suction device to eliminate dust contamination. (OPTIONAL)

[/wptab]

[/wptab]

[end_wptabset]