[wptab name=’RO system’]

RO System

Scope of application

Pure water in such industries as electronics, medicine and foodetc; purification for water used in textile industry and chemical industry; purification and preparation for water used in food and enological process; concentration and recovery of the useful materials of aqueous solution in industrial production ; preliminary desalination processing of high pressure boiler make-up water of the enterprises, such as electrical power plant, etc; brackish water and seawater desalinization; as the first class desalinating equipment for high purity water production.

[/wptab]

[wptab name=’RO+EDI system’]

RO+EDI System

Details

EDI equipment belongs to fine treatment water system and usually used in cooperation with reverse osmose (RO) to constitute the ultrapure water treatment system with pretreatment, reverse osmose and EDI equipment replaced the mixed ion-exchange unit used in traditional water treatment technology。 EDI equipment requires the electrical resistivity of the water to reach 0.025-0.5MΩ.cm and the reverse osmosis device can completely meet the requirements. EDI equipment can produce ultrapure water with the electrical resistivity above 15MΩ.cm.

[/wptab]

[/wptab]

[wptab name=’Hot water disinfection purification’]

Hot water disinfection purification water system

Pure water equipment requirements:

The water quality meets all the provisions of China pharmacopoeia standard and FDA

Automatic equipment operation and conditional automatic processing program (such as back flush, regeneration, acid-washing and disinfection procedures)

Monomer and pipe equipment meet GMP requirements (all such back end processing equipments as sterilizer, membrane filtration,terminal water tank and pipeline adopt SUS304 material).

[/wptab]

[/wptab]

[wptab name=’Second class RO+EDI’]

Second class RO+EDI purified water system

Pure water quality standards:

Electrical conductivity:≤0.5μs/cm

TOC≤200ppb

Microorganism≤20cfu/ml

[/wptab]

[/wptab]

[wptab name=’S series multi-effect water distiller’]

S series multi-effect water distiller

S series multi-effect water distiller is designed according to the principle of falling film and multiple-

stage evaporation. The first effect is to conduct heating by external heat source (industrial steam) and then each pillar can get enough heat energy by using the pure vapor produced from the fore-effect. The material water that did not evaporated in the first effect can be taken as the material in the next effect and so on.

Equipment features:

The whole equipment is made by 316L stainless steel and the operation surface is conducted with acid-washing and passivating treatment;

The pipeline system adopts the mirror polish 0.6μmRa 316L stainless steel tube and conducts with automatic track welding and connects with clean flange and pharmaceutical level gasket.

Use material wool to keep warm and the exterior of the equipment is covered with 314stainless steel matter finishing protective layer and its scaffold is made of stainless steel.

[/wptab]

[/wptab]

[wptab name=’F series multi-effect water distiller’]

F series multi-effect water distiller

F series multi-effect water distiller adopts Level 3 centrifugal separation technology. Siemens S7 series control system has Chinese and English operating language,water inlet booster pump with standard configuration, dashpot and collection tank. The equipment is equipped standard with plant steam reducing valve, the device for continuous emission of non-condensable gas. In addition, the F series equipment continuously discharge the residual liquid and record the electrical conductivity of water for injection and the valve location。 It is conducted with complete equipment manufacture factory acceptance test and the inlet water uses deionized water or RO water.子水或RO水。

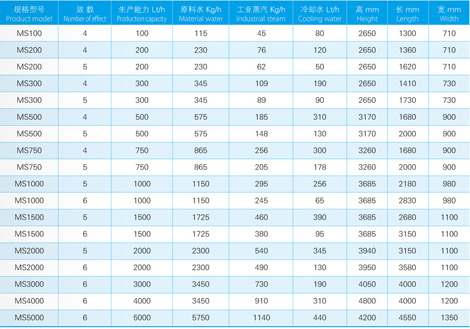

Technical parameters of F series multi-effect water distiller

Inlet pressure of industrial steam is 0.3MPa and the inflow working pressure of cooling water is 0.2MPa

[/wptab]

[/wptab]

[wptab name=’B series multi-effect water distiller’]

B series multi-effect water distiller

B series multi-effect water distiller adopts rising film and multi-diversion form to evaporate. The industrial steam enters the evaporate shell pass through valves and interchange heat with the purified water rising film in tube pass. The purified water after heat exchange becomes vapour, then impure heat source will be removed from the vapour through diversion separation device in the machine to produce the secondary steam. The pure steam after steam-water separation will become distilled water after being condensated as heating source in Ⅱ effect. Then the distilled water will enter into the condenser under the pressure differential action and then enter the storage tank through the pipe for storage. The concentrated water without evaporation and separation shall enter the next effect for re-evaporation through concentrated water inlet

Equipment features:

Adopts rising film for evaporation to solve the problem of uneven distribution of water.

High thermal efficiency, 100% heat exchange.

Save industrial steam consumption, 20% energy saving.

Distribute feeding water consumption amount for each effect accurately to reduce material water loss.

No need to exchange the multi-diversion separation device and life-span of the equipment can be extended.

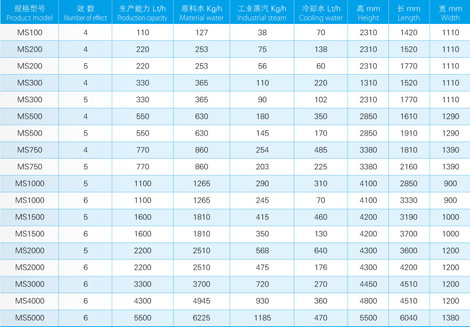

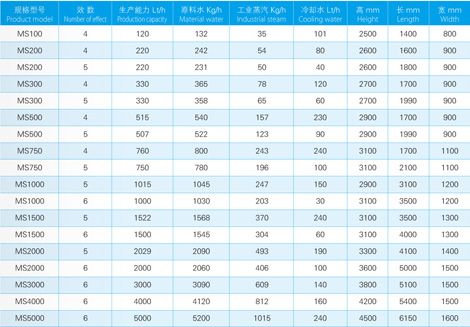

Technical parameters of B series multi-effect water distiller

Inlet pressure of industrial steam is 0.3MPa and the inflow working pressure of cooling water is 0.2MPa

[/wptab]

[/wptab]

[wptab name=’Clean steam generator’]

Clean steam generator

Production capacity:

The standard equipment model table shows the equipment production capacity under the condition of 3bar pure steam pressure and 6bar industrial steam with the unit in kg/h. The actual production capacity of some type equipments shall be acquired in accordance with the actual operation pressure and use this actual operation pressure to multiply the conversation coefficient in the specified production capacity。

Model selection example: Public facility demand:

Industrial steam pressure:7bar Industrial saturated steam without impurities and corrosive materials,

Pure steam pressure needed:2bar the maximum pressure is9bar。

The highest demand of pure steam:500公斤/小时 Feeding water requires deionized water without

Conversion coefficient:1.7 impurities and corrosive materials, the maximum pressure is 9bar.

Specified output needs:500/1.7=294kg/h Power supply standards:according to the clients’ required is 6bar.

Model selected:PSG 300 DTS Dry, oil-free and clean compresses air, the minimum pressure required is 6 bar.

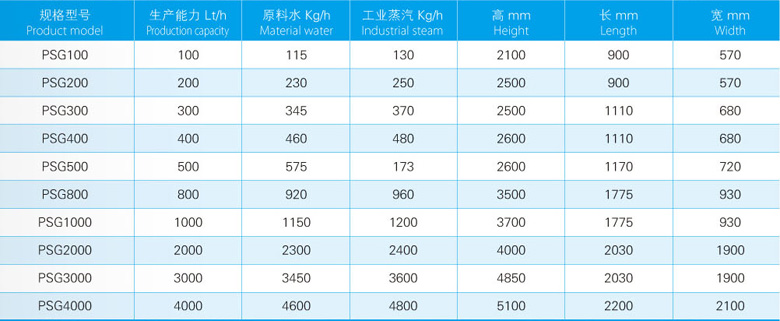

Technical parameters of Clean steam generator

Technical parameters of Clean steam generator

Inlet pressure of industrial steam is 0.3MPa and the pure steam working pressure is 0.2MPa

[/wptab]

[wptab name=’Pure water storage distribution system’]

Pure water storage distribution system

Distribution system is specially designed according to customers’ real situation on the basis of GMP, IPSE and FDA guidelines. The system adopts the frame structure and has such advantages as space-saving, plug-and-play and convenient installation. It will be conducted with preinstallation and operational qualification at the manufacturing plant. All the pipelines use the 316L stainless steel without dead leg and the sanitary type chuck connection mode. The roughness of the surface contacted by all products shall be less than 0.6μm. There is no buffering tank in the loop to avoid bacteria growth, which is in compliance with FDA requirements.

[/wptab]

[wptab name=’Distilled water storage distribution system’]

Distilled water storage distribution system

Distribution system is specially designed according to customers’ real situation on the basis of GMP,ISPE and FDA guidelines. All the pipelines use the 316L stainless steel without dead leg and sanitary type chuck connection mode. The roughness of the surface contacted by all products shall be less than 0.6μm. All the pipe fitting choose ASME-BPE2000 type accessories, which can realize thermostatic control automatically and operate with the water distiller in chain. All the control values are imported. The whole system can be conducted with the pre-installation and operational qualification at the manufacturing plant and the comprehensive validation documents are provided.

[/wptab]

[/wptab]

[wptab name=’Stationary CIP workstation’]

Stationary CIP workstation

CIP cleaning device can be used as the indissoluble production equipment and can also be used in the cleaning system with manual operation and automatic operation. The device is nearly used in such plants as food, drinks and pharmacy, etc. CIP device can not only clean the machine, but can also control the cleaning methods of microorganism.

[/wptab]

[/wptab]

[wptab name=’Mobile CIP workstation’]

Mobile CIP workstation

CIP cleaning device has the following advantages:

Can make the production plan reasonable and improve the production capacity.

Compared with hand cleaning, CIP does not affect the cleaning effect due to different operators, but can also improve product quality.

Can avoid the danger in the cleaning operation and save labor force.

Can save the cost of cleaning agent, steam, water and production.

Can increase the service life of machine components.

CIP cleaning devices include such three types as manual operation, semi-automatic and automatic for the selection by the users.

[/wptab]

[/wptab]

[wptab name=’Biological products tank equipment in batching system’]

Biological products tank equipment in batching system

Automatic welding equipment that can manufacture stainless steel pressure vessel.

Three kinds of technologies for surface treatment of the stainless steel container:

400#+electrobrightening Ra 0.4μm; 400#+600#+800#+2 electrobrightening Ra 0.28μm

Surface sandblasting and surface matte sanding Ra≤0.6

Electrolytic polishing technolagies and devices

Workshop and equipment for mechanical mixing.

Possess the devices for physical and chemical analysis of materials, thickness inspection and inner surface roughness test. The equipment design and manufacturing are totally in compliance with FDA requirements; the pressure vessel meets the national relevvant standards and the requirements for pressure vessel safety inspection; meet the requirements for equipment installation.

[/wptab]

[/wptab]

[wptab name=’Fermentation tank system’]

Fermentation tank system

HF series bioreactor is the ventilating machine stirred tank reactor and adopts PLC+color touch screen system intelligent control, which can meet the requirements for usage from the lab to pilot plant test and scale of production.This system has such advantages as simple structure, convenient operation and high degree of automation. It is widely used in such fields as edible mushroom, medicinal fungus liquid seeding, biological pharmacy, food additives, organism oil-recovery, biological energy source, biopesticide, bio-fertilizer, biological feed enzyme preparation and vitamin, etc.

The control parameters mainly include: temperature, rotating speed, ventilatory capacity, tank pressure, pH, Do, feed supplement, defoaming, biomass liveweight and scaling, etc.

Volume: 5L-500m³

[/wptab]

[/wptab]

[end_wptabset]