[wptab name=’Tablet Processing Line’]

Yenchen has been specializing in manufacturing Pharmaceutical Machine in Taiwan for many years. We mainly provide Pellet Machine, Coating Machine, Extraction Machine, Sterilizer and Ointment Equipment which can be widely applied to Pharmaceutical, Food and Chemical Industry. In addition, our main products also include High Shear Mixer, Fluid Bed Dryer, Oral Dosage Equipment and Dry Granulator. As a leading manufacturer of Pharmaceutical Machine, we offer above mentioned products with superior quality.

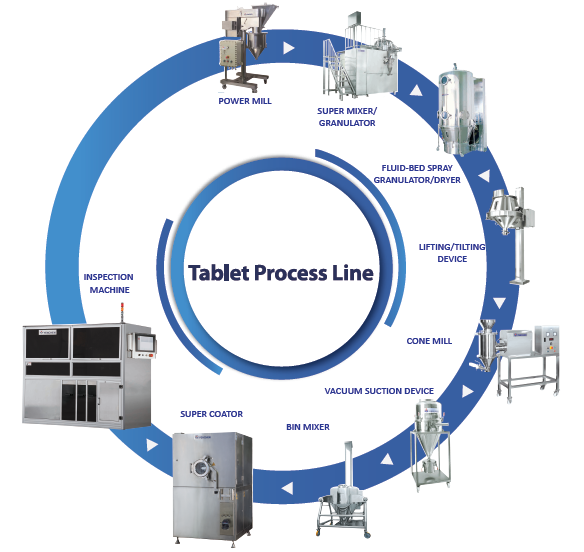

The process of middle and large volume:

Milling -> Mixing -> Granulating -> Drying -> Discharging -> Dry Granulating -> Vacuum Suction -> Final Mixing -> Tableting -> Coating

[/wptab]

[/wptab]

[wptab name=’High-Speed Rotary Tableting Machine’]

Product Features:

Efficient medium size production runs, with capacity up to 100,000 tablets per hour. Laboratory and pilot plant studies.

- Accurate tableting

- Compression in two stages

- Tableting compartment separated from drive mechanism

- Easy maintenance & cleaning

- Meets GMP

[/wptab]

[wptab name=’High-Speed Single Sided Rotary’]

Product Features:

Product Features:

- 10 ton Pre & Main compression

- Up to 169,000 tph

- Large fill zone

- High capacity power and gravity feed frames

- Accurate tableting

- Compression in two stages

- Tableting compartment separated from drive mechanism

- Easy maintenance & cleaning

- Meets GMP

[/wptab]

[wptab name=’Double – Sided Rotary’]

Product Features:

Product Features:

- High tablet output to 312,000 tablets per hour (tph)

- Max Pre-compression to 3 tons

- Max Main compression to 10 tons

- Bi-Layer tableting option

- For large batch production

- Allow for single layer tableting with double-sided output

- Accurate tableting

- Tableting compartment separated from drive mechanism

- Mechanical compression system

- Easy maintenance & cleaning

- Meets GMP

[/wptab]

[wptab name=’Pallet Equipment’]

Fluid Bed Dryer, Granulator, Coater:

Fluid Bed Dryer, Granulator, Coater:

Top Spray Granulation: Spray atomized binder or active ingredients on the fluidized to form the uniformity granules.

Bottom Spray Coating: The concept of Bottom Spray Coating is also known as Air Suspension Coating, is to separate pellets or granules from one another in an air stream and spray a coating binder onto the pellets or granules while they are suspended. When the hot air passes through the bottom screen of a container and draft tube (Wuster insert), it will generate the siphon principle. The granules will fall down and will be sucked into the draft tube (Wuster insert) again, while the bottom spray gun will spray towards top to achieve coating purpose.

Side Spray Powder Coating/Film Coating: The Side Spray is better for coating with high firm content. The cores (seeds) are placed on the turntable and hot air is blown upward between the turntable and the granulation area. The

coating solution is sprayed on the rolling cores through the pump and spray gun. The process involves simultaneous coating and drying of the cores, the repeated actions achieve the desired coating thickness or granule size. Powder Coating is achieved by charging powder and spray binder at the same time.

Functions:

1.Drying: Wet powder or granules drying

2.Top Spray: Spray binder on powder for granulation

3.Bottom Spray: Pellet Suspension Coating or Film Coating, Enteric Coating

4.Side Spray: Pellet Powder Coating, Suspension Coating or Film Coating, Enteric Coating

5.(Aqueous or organic solvent are applicable)

Suitable for:

Granulation/Drying>Pellet (Controlled-Release Coating): Film Coating, Enteric Coating and Powder Coating

Optional devices are available:

1.Double Shaking type of FBDD, basic machine with drying system is available to add on:

1.Top Spray Granulation: Provide powder granulation function

2.Bottom Spray Coating: For Pellets Film Coating or Enteric Coating functions

3.Side Spray Coating: For Powder Coating granulation, Pellets Film Coating or Enteric Coating

2.Explosion Proof System (when organic solvent is used):

1.2 Bar pressure resistant design:Suitable for 1 floor plant or the room is on the top floor(Safety relief duct towards up)

2.2 Bar pressure resistant design:Suitable for the room beside outdoor(Safety relief duct towards back)

3.10 Bar pressure resistant design: No safety relief duct

4.Safety relief duct: An organic solvent is not used

3.WIP or CIP system

4.Dehumidifier device

4.Dehumidifier device

5.Dust collector system

6.High accuracy air volume/pressure measuring device

7.Powder leakage detector

8.Suction device (Or connect with YENCHEN’s Super Mixer and Granulator)

9.Vacuum discharge (Closed type)

10.Lifting and tilting device

Features:

1. Follow the regulations of cGMP, PIC/S GMP, FDA

2. Multi-purposes: One machine can perform multiple functions, Drying, Granulation, Powder Coating, Pellet Film Coating, Pellet Enteric Coating

3. High drying efficiency: YENCHEN’s FBDD is 10 ~ 20 times faster than conventional drying oven

4. Temperature control can be controlled from room temperature to 100℃, law

temperature drying at 35-40℃ and an optional dehumidifier can be installed for thermo-sensitive product like probiotic

5. The inlet air is filtered by a final-filter to secure the cleanness of the inlet air

6. Touch Screen Interface control system: All the parameters can be memorable, multilevel of passwords can be set, connect to the diagrams printing are optional available

7. Two sets of valves are interacting automatically to suspend the granules continuously

Application:

1.Top Spray:

1.Pharmaceutical: For medicines, biopharmaceutical, and Chinese medicine’s granulation or drying

2.Food: Instant food, juice powder, seasoning, food additive,lactic acid bacteria’s granulation or drying

2.Bottom & Side Spray: Medicines and healthy food for a controlled release of active ingredients

Centrifugal Coater Granulator:

We not only provide Centrifugal Coater but also offer Wet Granulator, Through Circulation Dryer and Roller Compactor.

Two types fo spray gun:

a. for suspension coating

b. for granule / coating use

The following functions are adjustable

a. Temperature

b. Speed charging speed

c. Powder charging speed

d. Spray gun volume / pressuer

e. Air flow

Slight glass allow:

Observation of the operations and the status of the products during the process that enhances the chances of success by the allowing adjustment of the production parameters.

1.Production scale up model is accommodated by the pneumatic discharge system for easy operation.

2.Blowe, dust collector can be installed in the technical utilities area.

3.WIP auto cleaning system is available for production scale up model. (Optional)

4.Electricity or steam heating system is available.

5.Air inlet with cooling system available for easy control of the hot air temperature.

6.Explosion proof system available for organic solvent processes. (Optional)

7.Dust Collector. (Optional)

8.Operator interface. (Optional)

9.Dehumidifier facility can be incorporated to assure product quality. (Optional)

Applications:

Pharmaceutical, Cosmetic, Agriculture Products, Nutritional (Health) Food.

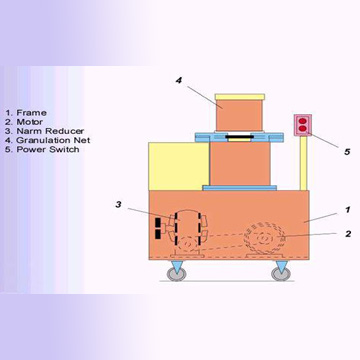

Wet Granulator Extruder:

Wet granulator is designed to process wet power into long shape granule.

Features:

1. High Production output.With fine and even sized granule.

2. Ease of screen changeover.

3. Continuous granulation.

4. Meet with G.M.P.standard and easy to clean.

[/wptab]

[/wptab]

[wptab name=’Tablet Coating Machine’]

1. Well mixed syrup with tablets are very easy for operation

2. Fully Automatic design, easy for operation and time saving for training operator

3. Uniform coloring, less weight deviation, and smooth coating

4. Fast production time takes 6~12 Hrs/Batch

Functions

1. Film Coating: Coat with a uniform and a thin protection layer on he tables. (Aqueous or organic solvent are applicable)

2. Enteric Coating: Coat with a uniform protection layer on the tablets to against the gastric acidity.

3. Sugar Coating: Coat with sugar protection layers on the tablets.

Film Coating Process

1. Preheating → Film Coating → Drying → Cooling → Finish

Principles of the Super Coater

1. Film / Enteric Coating:

Pump the solution to a spray gun then spray onto the tablets in the tumbilng pan and continuous dry by heated air to form a uniform and a thin layer on the tablets surface.

2. Sugar Coating:

The syrup spray to the tablets by a metring pump, then through the repeated process of tumbling, cooling and drying to form a thick sugar layer in order to protect the tablet.

Optional device are abailable

1. Explosion proof system (Organic solvent is applicable)

2. WIP or CIP system

3. Touch Screen Interface control system

4. Temperature recorder

5. Dehumidifier device

6. Dust collector system (Wet or Dry types)

7. High accuracy air volume / pressure measuring device

8. Weighing system (To observe the changing of the solution)

9. Preparation tank

Features

1. Follow the regulations of CGMP, PIC/S GMP, FDA

2. One equipment can perform multiple functions: for Film Coating, Enteric Coating, and Sugar Coating

3. Punched hole of a coating pan design: High drying efficiency

4. Short operation time: For Film, it takes 1-3 Hrs /Batch

5. Short operation time: For Enteric, it takes 3-4 Hrs /Batch

6. Short operation time: For Sugar, it takes 6-12 Hrs /Batch

7. Data recordable for whole process of the Coating Machine: Easy for an operator training

8. Multi-Safety Interlock System: For operator’s safety and quality assurance

9. Auto discharging system is optional available for labor saving purpose

10. Auto dampers designed of inlet and outlet air: The design of the equipment is to secure dampers are operated by pneumatic and easy to control and adjust

11. The Coating Machine is equipped with Touch Screen Interface control system: All the parameters can be memorable, multilevel of passwords can be set, connect to the diagrams printing are optional available

12. The inlet air is filtered by a final-filter to secure the cleanness of the inlet air

13. A cantilever design of the spray guns rack is precisely equipped on the equipment, easy for operation (A slide track design is for the bigger model)

14. Changeable pans design: Different size of the pans can be used in one equipment

[/wptab]

[wptab name=’Automatic Tablet Inspection’]

Inspection efficiency up to 120,000 tablets/hour

Inspection efficiency up to 120,000 tablets/hour

Optical inspection principle:

Automatic optical inspection is a common method in industrial processes. In the use of optical instruments to obtain the surface state of the finished product, and then inspect foreign objects, abnormal patterns and other defects by the computer image processing technology. Tablet inspection machine is used the optical illumination and image measurement technology to inspect size mismatch, surface foreign object, pucker, stained, breakage, twining of the tablet.

Features

1. Follow the requirements of cGMP、PIC/S、21CFR Part 11

2. Using high-sensitivity CMOS CCD to take high-resolution images. Inspect hair and foreign objects, adhesion of dirt and foreign matters, improve the detection accuracy of the edge of the tablet.

3. High-speed image processing technology to improve the quality of inspection process and save manpower.

[/wptab]

[wptab name=’Tablet Processing Machine’]

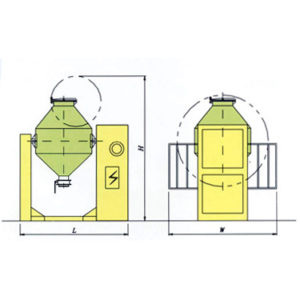

Double Cone Mixer

The corn shaped mixer is wide in the middle and narrow of the both ends. Inside has bottles in the middle, when the powder or granules rolling up and down in he drum and hit the middle bottles, the best mixing result can be reached.

Features:

1. Well mixing effect

2. Simple structure

3. Mixing ratio up to

4. With safety gate and safety interlock

5. Can join with vacuum suction system and connect to dry granulator for closed type operation and continuous auto loading

[/wptab]

[end_wptabset]